Despite mounting uncertainty surrounding clean transport policy under the latest US administration, ACT Expo 2025, the largest clean transportation event worldwide, showed no signs of slowing down. If anything, it felt bigger and busier than ever, reports Will Shiers, ITOY jury member UK.

Held at the Anaheim Convention Center in Los Angeles (April 28-30), the event attracted more than 500 exhibitors, over 12,000 pre-registered attendees, 300 speakers, and close to 200 zero- or low-emission trucks and vans. From battery-electric to hydrogen, a handful of gas-powered stalwarts, and even the occasional rogue diesel truck, the industry gathered to showcase progress, debate direction, and prepare for whatever comes next.

FREIGHTLINER

ACT Expo may now be dominated by battery-electric and hydrogen vehicles, but gas power still has a strong presence. When the event first launched, it was very much a natural gas show, and reminders of those roots remain. Parked proudly outside the Anaheim Convention Centre, this Penske-liveried Freightliner Cascadia marked the official launch of the model fitted with the Cummins X15N natural gas engine. Its presence served as a powerful reminder that compressed natural gas still has a meaningful role to play in the transition to cleaner transport.

VOLVO

Volvo Trucks showed a fully autonomous diesel-powered VNL on its stand.

The truck, developed in collaboration with Aurora, is currently operating autonomously with a safety driver on a freight route between Dallas and Houston, Texas. The next phase will see operations expand to a longer corridor between El Paso and Houston, with the ultimate goal of removing the driver altogether.

“We are not just testing technology, we are running real freight with real customers,” said Sasko Cuklev, head of on-road solutions for Volvo Autonomous Solutions. “Everything we’re building is designed to scale, using the existing road infrastructure without modifications.”

The autonomous VNL integrates Aurora’s virtual driver with Volvo’s own autonomy-enabled truck platform, featuring full system redundancy for critical functions such as steering and braking.

“Our approach has always been to build safety into the truck from the ground up,” added Nils Jaeger, president of Volvo Autonomous Solutions. “We are following a structured deployment process, starting with safety drivers, then moving to full autonomy once all safety cases are satisfied.”

The VNL autonomous truck is part of Volvo’s broader strategy to tackle long-haul routes, which are increasingly difficult to staff due to an ongoing driver shortage. By focusing initially on predictable highway corridors in states like Texas, Volvo aims to accelerate the safe commercialisation of autonomous freight.

Volvo’s New River Valley plant in Virginia has already been upgraded to produce autonomy-ready trucks at scale, ensuring the company is ready for wider deployment as regulations and market acceptance evolve.

HYUNDAI

Hyundai has unveiled its latest XCIENT Class 8 fuel cell electric truck, marking a major step forward in its zero-emission commercial vehicle programme for North America.

Powered by two 90kW hydrogen fuel cell stacks and a 72kWh battery, the XCIENT delivers 350kW of continuous power and up to 2,237Nm of torque. With a maximum range of 450 miles, the truck features 10 hydrogen tanks holding approximately 68kg of fuel, offering fast refuelling and long-haul potential.

Tailored specifically for the US market, the updated XCIENT includes a refreshed cabin design and a full suite of Advanced Driver Assistance Systems (ADAS), designed to improve driver safety and comfort during extended operations.

Hyundai also revealed it is working with autonomous tech specialist Plus to integrate Level 4 autonomous driving into the XCIENT platform, a move aimed at boosting freight efficiency while reducing driver workload.

“By combining hydrogen fuel cell technology with cutting-edge autonomy, we are shaping the future of sustainable freight,” said a Hyundai spokesperson.

Production and commercial deployment timelines are yet to be confirmed, but Hyundai says this latest XCIENT represents its most advanced heavy-duty fuel cell truck to date.

HARBINGER

California start-up Harbinger made its ACT Expo debut with what it claims is the industry’s first purpose-built hybrid chassis for medium-duty commercial vehicles. Aimed at fleets with long or unpredictable routes, it pairs a 140kWh or 175kWh battery with a 1.4-litre petrol range-extender, offering up to 500 miles between charges.

Built at Harbinger’s Garden Grove facility, the platform supports a wide range of body styles. Production starts in 2026. Both hybrid and all-electric versions were on display, with Harbinger positioning itself as a price-parity alternative to diesel.

AUTOCAR

Autocar, the US’s oldest automotive brand, has unveiled its new DC Fuel Cell truck — a hydrogen-powered, severe-duty conventional vehicle developed in collaboration with General Motors and Triz Engineering.

Built for demanding vocational applications, the truck is powered by two GM Hydrotec fuel cell power cubes, each delivering 77kW of continuous power, for a total of 154kW. Supporting the system is a 140kW battery, which helps manage peak power demands and improve performance under heavy load.

With a 54kg hydrogen tank capacity, the DC Fuel Cell offers a projected range of up to 425 miles. Power output is rated at 670hp and 2,170Nm of torque.

Although the fuel cell configuration adds some weight, Autocar expects states like California to allow weight exemptions for zero-tailpipe-emission trucks. Claimed system efficiency is 55%.

“This marks a significant milestone in our sustainability journey,” said an Autocar spokesperson at the launch. “The DC Fuel Cell delivers uncompromised performance while enabling fleets to join the hydrogen revolution.”

PETERBILT

Peterbilt has expanded its battery-electric lineup with the launch of two new models: the next-generation Model 579EV (pictured) and the all-new vocational Model 567EV.

The 579EV, designed for regional haul and drayage, offers up to 200 miles of range and 350kW fast-charging, reaching 80% in just over 90 minutes. Meanwhile, the 567EV is claimed to be the industry’s first electric vocational conventional, tailored for dump, utility and equipment applications with up to 250 miles of range and ePTO options rated at 25kW or 150kW.

“Peterbilt leads the industry with high-performance, zero-emission heavy-duty vehicles,” said Erik Johnson, assistant general manager of sales and marketing. “These models deliver the performance, safety and efficiency our customers demand.”

REVOY

Revoy has developed a battery-electric dolly that turns any diesel semi into a hybrid, with no modifications required. The self-powered unit sits between a standard tractor and trailer, providing propulsion support to reduce diesel consumption, particularly during acceleration and hill climbs. Each unit can be swapped in about five minutes at dedicated stations, eliminating downtime and the need for onsite charging.

Ryder is among the first fleets to pilot the system, operating units on the I-30 corridor between Memphis, Tennessee and Laredo, Texas. Instead of paying upfront, fleets are billed based on diesel savings, making Revoy a risk-free path to lower emissions. It’s billed as a practical, scalable bridge for operators not yet ready for full electrification.

MACK

Mack Trucks has launched a new on-highway model called the Pioneer, which is the successor to the Anthem long-haul tractor introduced in 2017. Justifying its presence at ACT Expo, president Jonathon Randall said the new model delivers up to 11% better fuel efficiency than its predecessor.

Featuring a more aerodynamic cab design, revised driver ergonomics and a new digital dashboard, the Pioneer is aimed at long-haul operators looking to cut fuel costs and improve uptime. It also comes with updated safety and connectivity features.

Mack announced it will be launching an electric version of the Pioneer in 2026, which will feature the newly developed Volvo Group eAxle.

ISUZU

Isuzu used ACT Expo 2025 to showcase its growing zero-emission strategy, providing updates on the NRR EV (pictured) and announcing a new electric F-Series truck in partnership with Accelera by Cummins.

Now in production at Isuzu’s Charlotte, Michigan facility, the Class 5 NRR EV is available with four battery options offering up to 235 miles of range.

Looking ahead, Isuzu unveiled plans for a battery-electric F-Series Class 6 and 7 truck, co-developed with Accelera. Scheduled for 2027 production, it will use LFP batteries, a 14Xe eAxle, and Cummins’ PCAS 3.0 control system.

RIVIAN

Rivian’s Commercial Van, originally developed for Amazon, is now available to fleet operators across the US. The all-electric van is aimed at last-mile delivery applications.

Built on Rivian’s electric platform, it features a flat load floor, wide-opening doors, and integrated telematics, designed to maximise efficiency and driver comfort in urban environments. Payload capacity and range options vary by configuration, with the vehicle tailored for high-utilisation delivery fleets.

Rivian is now targeting a broader commercial market, positioning the van as a flexible, zero-tailpipe-emission alternative for fleet operators looking to decarbonise without sacrificing functionality.

GM

General Motor’s BrightDrop Zevo 400 electric van is aimed at last-mile delivery fleets operating in tight urban environments. Smaller than the Zevo 600, the Zevo 400 offers up to 7cu m of cargo space and a GM-estimated range of up to 250 miles, depending on conditions.

Built on GM’s Ultium platform and sold through its Envolve commercial division, the Zevo 400 features a low step-in height, wide-opening doors, and a focus on ergonomics for high-frequency delivery routes. It’s part of GM’s growing push to electrify its commercial vehicle offerings.

BOLLINGER

Bollinger Motors unveiled its production-ready B4 electric truck, with the first stripped chassis cab now headed to EnviroCharge for upfitting as a mobile charging unit. The Class 4 cab-forward model is the first vehicle to enter series production under Mullen Automotive ownership.

Powered by a Dana rear eAxle and dual 79kWh lithium iron phosphate battery packs from Our Next Energy, the B4 delivers up to 185 miles of range and supports both Level 2 and DC fast charging. With a GVW rating of 7 tonnes and a payload capacity of over 3,300kg, it’s aimed squarely at urban and regional fleet operators.

Built from the ground up for electrification, the B4 features flat frame rails and a modular design for easy upfitting. Assembly is handled by Roush Industries in Livonia, Michigan.

TESLA

Tesla is forging ahead with its electric truck ambitions, announcing a nationwide rollout of dedicated Semi charging hubs across the US. Speaking during a presentation at ACT Expo, Dan Priestley, senior manager for the Tesla Semi program, confirmed that 46 public charging sites are already in development, with more than 300 megawatt-capable posts expected to begin installation this year.

Priestley reaffirmed Tesla’s commitment to scaling electric freight through both product and infrastructure. Series production of the Semi is set to begin in 2026 at the company’s expanded Gigafactory in Nevada, which now spans 158,000sq m. The site will eventually support an annual output of 50,000 units, with manufacturing equipment being installed throughout 2025.

Initial units will be deployed in Tesla’s own logistics operations, with wider customer deliveries to follow. Two variants—standard and long-range—will be offered, both targeting best-in-class range, weight and efficiency. Real-world testing is well underway, with pilot vehicles having already logged 7.9 million miles.

Tesla says customer feedback has informed several product refinements, including revised aerodynamics, improved visibility, and enhanced driver comfort. A new in-house battery pack will reduce both cost and weight, while maintaining range thanks to a 7% reduction in drag. The Semi will support over 1 megawatt charging using the Tesla NACS inlet.

He said Tesla’s new 1.2MW fast chargers—adapted from its Supercharger technology—offer a 50% footprint reduction and are key to unlocking high-volume deployment. Public and private versions will support operations nationwide, especially for fleets facing site constraints.

Priestley also confirmed the addition of an electric power take-off (ePTO) system, allowing the Semi to power refrigerated trailers and auxiliary equipment—bringing Tesla a step closer to fully electrified vehicle-trailer combinations.

While Tesla did not have a stand at the event, a Semi was displayed on the WattEV stand.

VOLVO

Volvo Trucks North America has announced that its VNR Electric (pictured) has now surpassed 15 million miles in customer operation, reinforcing the company’s commitment to zero-tailpipe-emission transport solutions. Since commercial sales began in December 2020, more than 700 VNR Electric trucks have entered service across the US and Canada, operating in fleets ranging from solo owner-operators to those with over 100 electric trucks.

“We know these are challenging times for zero-emission adoption, with delays in charging infrastructure and regulatory uncertainty,” said Peter Voorhoeve, president of Volvo Trucks North America. “But customers continue to defy the odds, and we’re proud to lead the market in battery-electric trucks.”

Volvo is also preparing to launch the all-new VNL Electric, which will feature an integrated eAxle to increase range by freeing up space for additional batteries. The official debut date has yet to be announced.

To support its growing electric customer base, Volvo now has 74 Certified Electric Vehicle dealerships across 29 US states and four Canadian provinces. Each location offers trained sales and service staff, and supports post-deployment care, including the Gold Service Contract covering batteries and preventative maintenance.

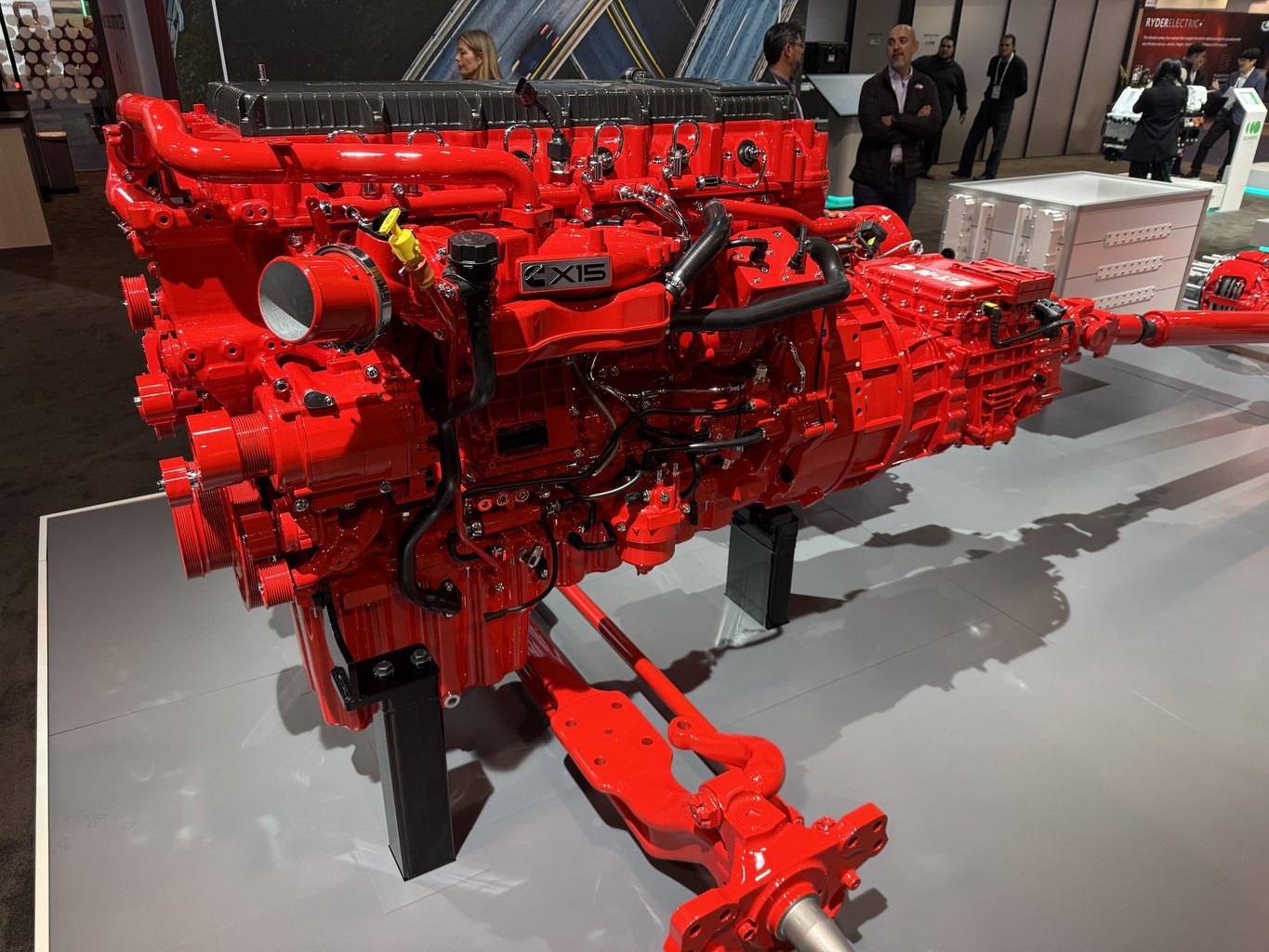

CUMMINS

Cummins and its zero-emissions brand Accelera used the show to present a wide portfolio of low- and zero-tailpipe-emission powertrain technologies for commercial vehicles. A key highlight was a concept hybrid powertrain built around Cummins’ 2027 X15 engine (pictured), paired with Accelera batteries and existing driveline components. The configuration demonstrates the company’s multi-fuel strategy aimed at reducing emissions across a variety of applications.

Also on display were the X15N natural gas engine and the X15H hydrogen internal combustion engine, alongside Cummins-Meritor Endurant HD and XD transmissions and 14X HE tandem drive axles.

Accelera’s contributions included the latest 14Xe eAxle with the ELFA motor and inverter, its new Power Control and Accessory System (PCAS), and a tiered LFP battery platform designed for both vocational and on-highway use.

The combined offerings reflect Cummins’ approach to supporting customers through the energy transition, with a range of power solutions to meet different operational needs.

“Whatever the duty cycle, whatever the fuel, we’re providing real, ready-now options,” said a Cummins representative. “This isn’t a vision—it’s a portfolio built for today and tomorrow.”

KALMAR

Kalmar and Forterra have unveiled the Kalmar Ottawa AutoTT, an autonomous terminal tractor designed to boost safety and efficiency in yards, distribution centres, and container terminals. Making its debut in the Ride & Drive at ACT Expo, the AutoTT is currently undergoing its second round of testing, with full production targeted for late 2026.

The collaboration combines Kalmar’s terminal tractor expertise with Forterra’s military-grade AutoDrive autonomous system. The AutoTT builds on Kalmar’s automation-ready platform, integrating drive-by-wire controls and autonomous hardware kits at its Ottawa, Kansas facility.

Initial deployment will be on the diesel-powered Kalmar Ottawa T2, followed by the T2 EV electric model. The system is tailored for complex environments, including sites with high manoeuvrability demands.

“This is a game-changer,” said Timo Alho, director of product management, automation at Kalmar. “We’re merging trusted tractor tech with cutting-edge autonomy to deliver a powerful, practical yard automation solution.”

KENWORTH

Kenworth launched two new battery-electric trucks, strengthening its zero-tailpipe-emission offering. The T880E (pictured) is a vocational Class 8 electric truck, engineered for demanding sectors like construction, tipping and refuse. It delivers up to 605hp and 2,508Nm of torque, offers more than 250 miles of range, and supports DC fast charging up to 350kW. Available in both set-forward and set-back axle configurations, it also features options for ePTO integration.

Joining it is the next-generation T680E, designed for regional haul, LTL, and drayage operations. With a 500kWh battery pack providing over 200 miles of range, the new T680E features improved aerodynamics and Kenworth’s latest 15-inch DriverConnect digital display. Both trucks include SmartWheel steering controls and optional advanced driver assistance systems, helping fleets meet zero-emission targets without sacrificing performance or driver comfort.